What started all of this?

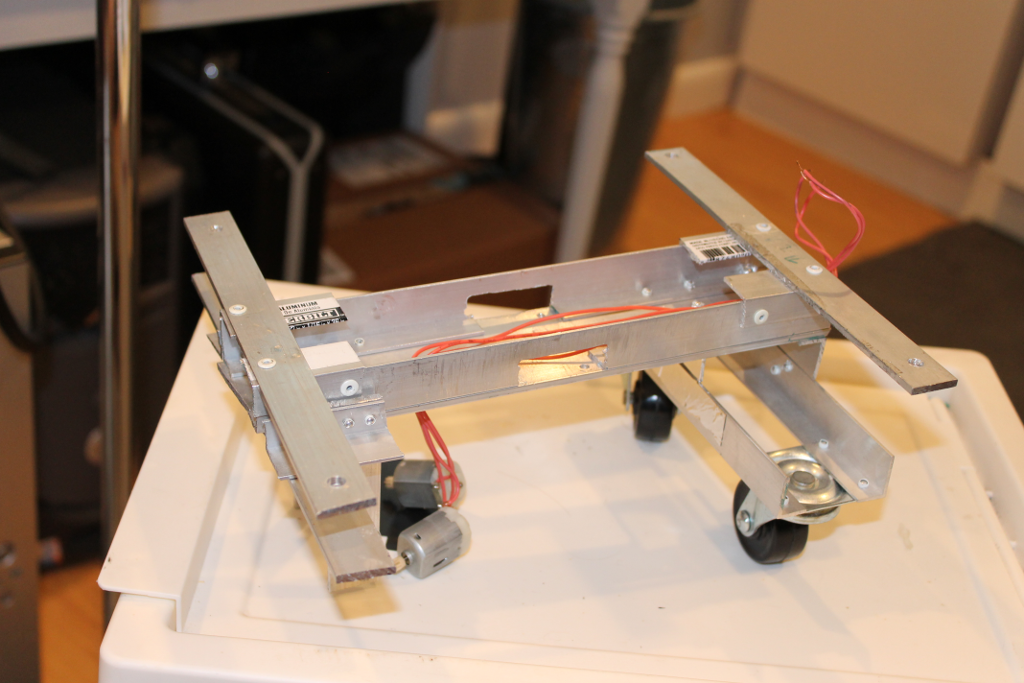

I must have come into the world with a screwdriver in my hand, since I have always loved seeing how things work and building new things. When I got to high school, I joined the Blair Robot Project, FIRST team 449. One of my experiences was using a pop riveter to make drive frames out of aluminum stock and laser-cut gusset plates. I wanted to build my own metal robot at home because riveting aluminum is so satisfying! My family already had a few hacksaws, tape measures, and drill bits, so I picked up a hand riveter and a center punch. Before long, I had a little frame together, almost ready to test. Now, I just needed some motors and a way to control them. I found some L293D chips and had my heart set on using a Raspberry Pi as a controller, using a 12-channel PWM Pi hat. Unfortunately, I wasn't familiar enough with network programming to write an application to control the Pi over a network live. So, my project went on hiatus for a few years.

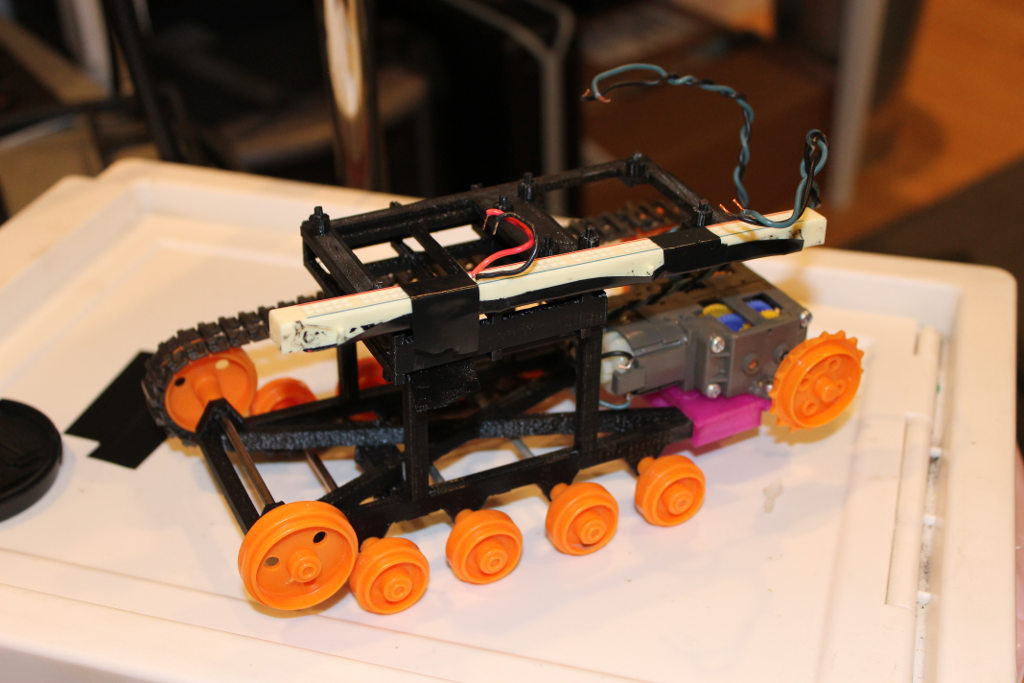

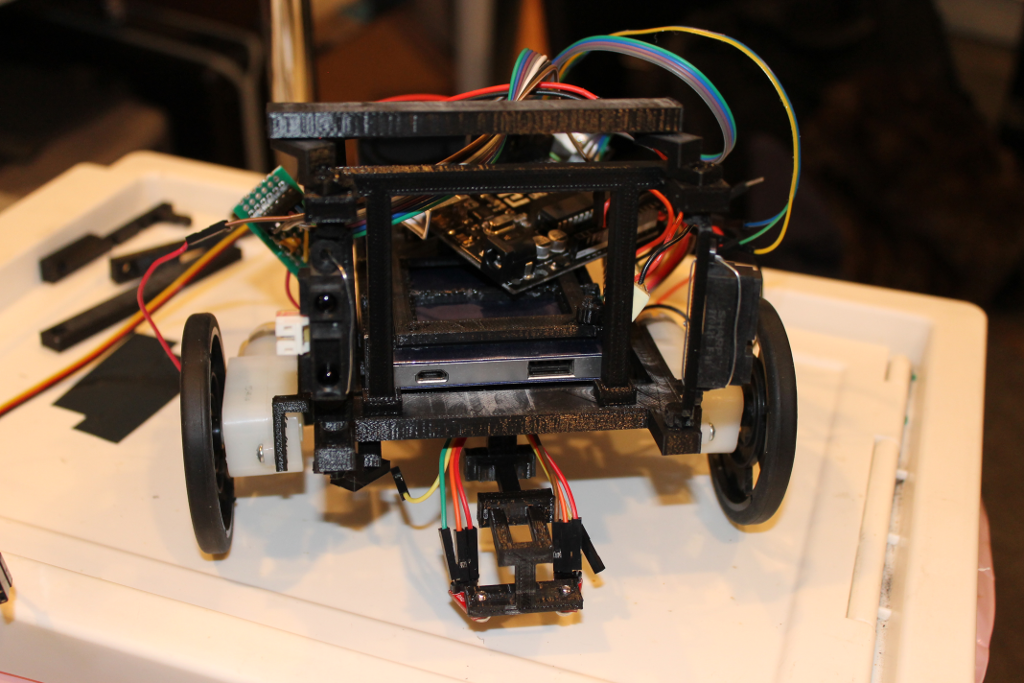

I have had to reuse some parts from the original frame, but some parts still remain.